Principle of operation

Principle of operation

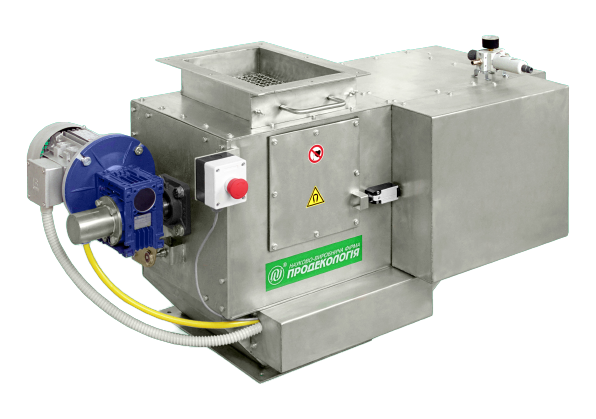

The initial product is fed evenly into the working area of the separator, depositing ferromagnetic impurities on the surface of the magnetic blocks.

Cleaning of the separator is carried out without stopping the technological process, by moving the magnetic system automatically from the working area into a zone of cleaning where ferromagnetic impurities are falled down. Moving the block, impurities additionally are released from product to be separated.

Design features of the separator

Design features of the separator

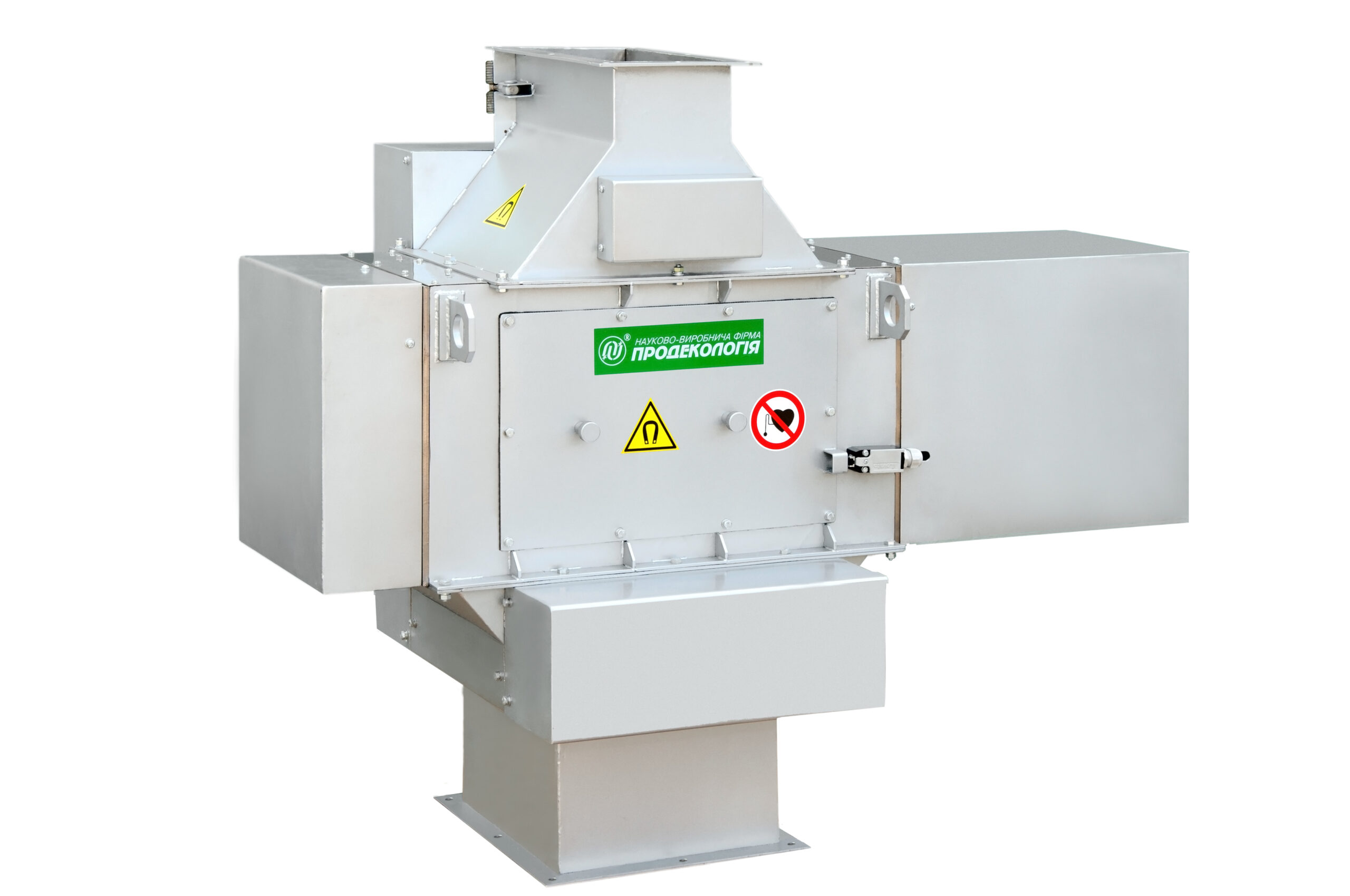

- Mounted on a vertical product pipelines and in the places for pick-and-place jobs.

- Depending on the efficiency one-or two-rotor system of placing the magnetic blocks in the amount of 8 to 24 pieces is used.

- Cleaning of the separator is carried out in the automatic mode, according to the specified cyclogram.

- Magnetic block is arranged by the principle of a pneumatic piston. Magnet system in form of a rod together with the magnets is moved inside the pipe under the action of compressed air.

- Rotation around the axis of the magnetic system prevents the formation of traffic jams and crosspieces of the cohesive product in the pipeline, and jamming of product to be separated.

- Minimal loss of a useful product at the separation process (up 0.1%).

- Components of the world leading companies (Nord, SKF) with high performance are used.

- Available with manual (SKR–R) and mechanical (SKR–M) cleaning.

Be the first to review “Rod rotary magnetic separator SKR-A” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.