History

An electrostatic separator EBS for the separation of shredded electrical cables was manufactured and delivered to a recycling company in Norway. Norway is the 51st country in the world where the company's equipment will be operated.

The geography of the company's deliveries has been expanded to 50 countries. An electric cable waste recycling line, consisting of a light fraction separator SLF and an electrostatic separator EBS, was shipped to a company from Palestine.

A line for processing crushed PVC window profiles, consisting of an corona electrostatic separator EBS, an triboelectric separator EBS-T, a magnetic drum separator BS, a light fraction separator SLF and a circular sieve, was delivered to Belgium. Thus, the company's supply geography was increased to 48 countries.

A pilot plant for iron ore beneficiation has been installed for the Egyptian enterprise. Egypt is the 47th country in the world where the company's equipment will be operated.

The geography of the company's deliveries has been expanded to 46 countries. An EBS corona-electrostatic separator has been shipped to the UK to remove non-ferrous metals from shredded electrical cable.

New equipment of the company - industrial plate electrostatic separator 4EPS - was manufactured and shipped. The equipment will operate in the fluorite-selaite ore beneficiation line.

Complex line for recycling PP + PE polymers mixture, consisting of triboelectric separator EBS-T and separator of light fraction SLF, was delivered to Turkey. This country became the 45-th in the company sales geography.

Canada is the 44-th country in the sales geography of the company! Complex of magnetic separators BS-RS for separation of mixture of metals was shipped to the recycling enterprise.

The sales geography of the company was increased to 43 countries: electrostatic separator EBS for processing crushed electric cable is delivered to Portugal.

New development of the company - NIR-separator "Sterkh" - was presented at the exhibition K'2019 (Dusseldorf, Germany). The equipment is intended for separation of polymeric materials by means of spectroscopic methods.

With the delivery of magnetic drum separator BS, cooperation with the enterprise of the 42-nd country of the world - Greece - began. The separator was purchased to purify Cu concentrate from ferromagnetic impurities.

On July 28, 2018 SMF “Prodecologia” celebrated its 25-th anniversary. In the same year, 100-th patent for inventions and utility models was received.

It was begun cooperation with the company from the Netherlands, which became the 41-st country. The triboelectric separator EBS-T, the corona electrostatic separator EBS and the magnetic separator BS for the separation of polymer mixtures were shipped.

The line for purifying PET flakes from impurities of PVC films consisting of the triboelectric separator EBS, separator of light fraction SLF and the sieve was shipped to the Indian company. This order has expanded the geography of company sales to 40 countries.

The electrostatic separator EBS for extraction of non-ferrous metals from crushed electrical cable wastes was delivered to the recycling company in Morocco. So that, the geography of company sales is extended to 39 countries.

It was begun cooperation with the company of the 38-th country of the world - Switzerland. The corona electrostatic separator EBS was shipped to the recycling plant for separation of the mixture of non-ferrous metals and polymers.

The laboratory electrostatic separator EBS was shipped to the partner of the company for the sale of equipment in Mexico.

For the first time, equipment was delivered to France, 36-th country in the geography of company sales. The triboelectric separator EBS was shipped for separation of the mixture of polymers PE + PP.

The electrostatic separator EBS for extraction of non-ferrous metals from crushed electrical cable wastes was delivered to the company from Bahrain. This is the 35-th country in the geography of company sales.

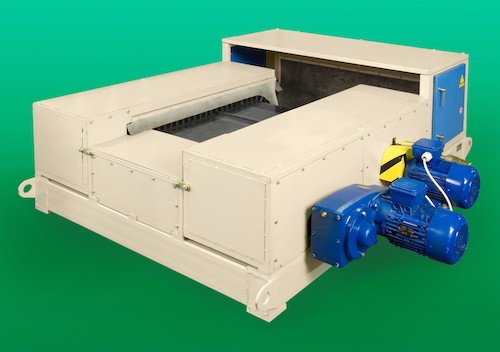

The eddy current magnetic separator for extraction of aluminum from shredded composite panels was delivered to the recycling company from the UAE. So that, the geography of company sales already counts 34 countries.

It was begun cooperation with the recycling company in Romania, which became the 33-d country where the electrostatic separator EBS was been shipped to.

The complex of equipment for the processing of crushed window profile, consisting of the electrostatic, magnetic separators and the metal detectors, was delivered to Hungary, which became the 32-nd country in the geography of company sales.

With the delivery of the electrostatic separator EBS, it was begun cooperation with the company from the 31-st country - Tunisia. The equipment is intended to purify PET-flakes from aluminum.

For the first time in history of the company equipment of SMF "Prodecologia" operates on the African continent - on the order of South Africa company was developed, manufactured and shipped electrostatic separator EBS. Therefore, the geography of supply now has four continents and 29 countries.

Manufactured and shipped electrostatic separator EBS for separation of shredded electrical cable. The equipment will be operated in the United States. Therefore, the geography of the company deliveries has 27 countries.

Manufactured and shipped electrostatic separator EBS for separation of shredded electrical cable. The equipment will be operated in the United States. Therefore, the geography of the company deliveries has 27 countries.

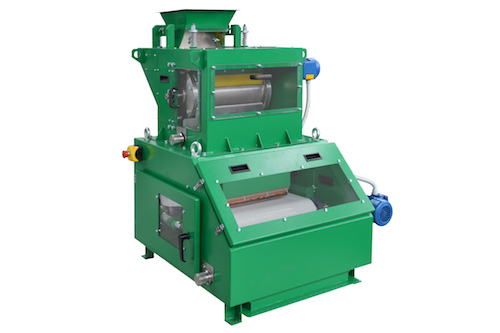

Designed, manufactured and delivered the complex of equipment with capacity 1t / h to the German company which recycles electric cable. The complex consist of 2 electrostatic (corona and triboelectric) and one magnetic drum separators. Germany has become 26th country our company working with.

he SMF "Prodecologia" equipment were first supplied to another hemisphere of the planet - the plate magnetic separator PN-A and the pulley magnetic separator SH were shipped to the company in Guatemala.

Was shipped electrostatic separator EBS, which is a part of the line for processing of electrical cable waste. It will be operated in Saudi Arabia. Geography of company deliveries now expanded to 24 countries.

For companies of Bosnia and Herzegovina was made the magnetic drum separator BS. With this delivery, the geography of cooperation companies for SMF "Prodecologia" has extended to 23 countries.

Was begun cooperation with the 22nd country - the Czech Republic. Manufactured and started to work sorting-processing complex SPC-1 to separate mixtures of polymers.

The geography of deliveries of SMF "Prodecologia" increased to 21 countries - for the Italian company was designed and manufactured the triboelectric separator for separation of polymers.

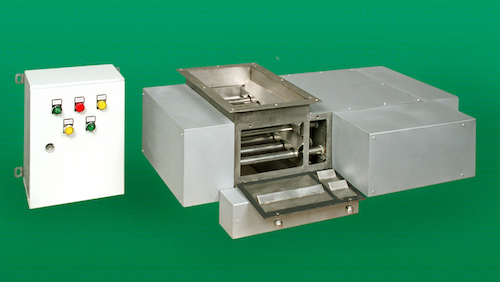

Designed and manufactured new triboelectric separator for separating mixed plastic waste (PET, PVC, rubber, PS, PP, PE, PP) and their components.

July 28, 2013 SMF "Prodecologia" turned 20 years. The anniversary awarded the beginning of cooperation with customers from 20th country.

The electrostatic separation is the new direction of the company mastered fundamentally.

The first electrostatic separator type ЕBS was successfully tested at the enterprise for processing of cables and wires.

The new eddy current separator type VS-Е tapeless with eccentric placement of magnetic drum is designed.

The new metal detector with digital signal processing type DMT3M is designed.

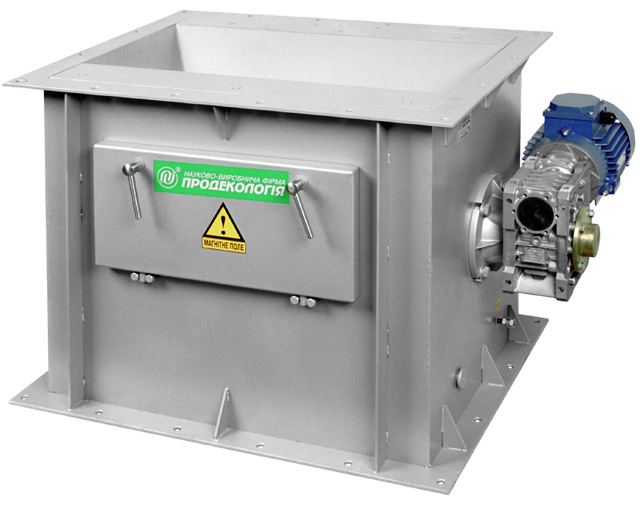

The new magnetic separator type BSHM for extraction of magnetic impurities (scrap) from the grinding products of ball mills in the automatic mode is designed. The first said separator was successfully tested at Ridersky GOK "Kazzinc", OOO (Kazakhstan).

The complex for dry magnetic benefication of oxidized ores according to order of GOK "Ukrmekhanobr" ОАО "ММК after Illich" was designed.

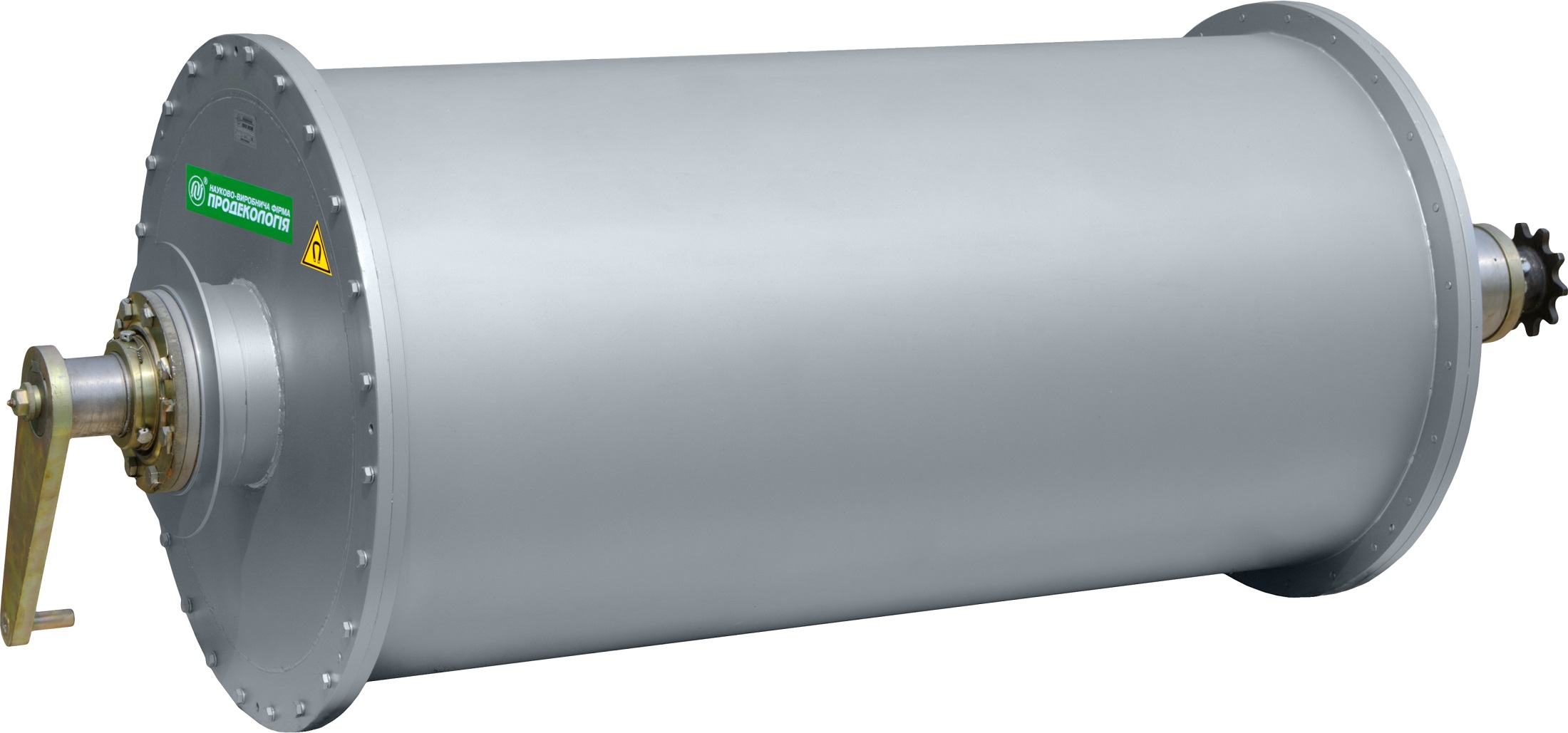

Testings of magnetic drum, designed for regeneration of weighting agent including a ferrosilicon, successfully were completed on Zyrianivsky GOK "Kazzinc" OOO (Kazakhstan).

The first eddy current separator for separation of container cullet was designed and supplied to "Gostomel Glass Company" ОАО (Ukraine).

The production of the wet drum separator is mastered. The first separator of said type was set on Irshansky GOK (Ukraine) for separation of crude ilmenite concentrate.

The magnetic drum separator of SMF "Prodecologia" production was successfully tested at "Aksu Ferroalloy Factory". According to the test results management of "TNK "Kazchrome" OAO decided to install separators of said type at the slag processing lines of all ferroalloy plants in Aktobe and Aksu cities.

The tender was won for supplying of metal detectors for equipping of forage harvesters type DON-680

The first magnetic rod separator with automatic cleaning was produced for "Novoselovsky GOK" ZAO (Ukraine).

The first drum separator for dry magnetic separation of chamotte was developed for OJSC "Vatutyn Ore Mining and Processing Plant" (Ukraine).

For the first time in Eastern Europe the eddy current magnetic separator of high intensity was designed and produced for concentration of non-metallic materials.

Output of magnetic mud clarifiers was mastered. The first delivery was realized for "Bereznofarfor" OAO (Ukraine).

The first deliveries of metal detectors were realized for different industries.

The successful mastering and start of delivery of magnetic separators to porcelain and faience, fat and oil industries.

The first serial deliveries of magnetic blocks to "Mohyliv-Podilsky Machine-Engineering Plant after S.M.Kirov" OAO (Ukraine).

The first magnetic separators were designed.

The first devices for magnetization were developed and delivered.

The first contract for the modernization of magnetic separators at the food industries was signed.